EVA is the abbreviation of Ethylene Vinyl Acetate Copolymer. EVA is a copolymer of ethylene and acetic acid. EVA is widely applied, and the consumption is getting increase year on year, especially in the shoe manufacturing industry, it is used in the soles and interior materials of mid-to-high-end tourist shoes like hiking shoes, slippers, and sandals. It is also widely used in the field of new energy, such as photovoltaic materials and solar cell adhesives

Introduction

Ethylene-vinyl acetate copolymer refers to EVA. Generally, the content of vinyl acetate (VA) is 5%-40%. Compared with polyethylene (PE), EVA introduces vinyl acetate monomer to the molecular chain, thereby reducing high crystallinity, improving toughness and impact resistance, filler compatibility and heat sealing properties.

Features

EVA is widely used in packaging molds, fitness products, hot melt adhesives, toys and other fields.

- Vinyl acetate content below 5% (films, adhesives, etc.);

- Vinyl acetate content between 5% and 10% (elastic films);

- EVA with 20-28% vinyl acetate is mainly used in hot melt adhesives and coating products;

EVA is made by copolymerization of LLDPE (linear low density polyethylene) and acetic acid (VA).

The polymerization method of EVA:

- High-pressure bulk polymerization (plastic products)

- Solution polymerization (PVC processing aid)

- Emulsion polymerization (adhesive products)

- Suspension polymerization

Emulsion polymerization is used when the content of vinyl acetate (VA) is higher than 30%;

High-pressure bulk polymerization is applied when the content of vinyl acetate (VA) is low.

The main factors affecting the performance of EVA:

- Melt Index Melt Index

- VA% The content of acetic acid

With melt index (MI) constant, the higher the content of vinyl acetate (VA), the higher its elasticity, softness, compatibility, transparency, etc. When the content of VA decreases, its performance is close to that of polyethylene (PE), the abrasion resistance and electrical insulation increase with the increase of rigidity.

When the content of VA is constant, the increases of melt index (MI) come in the decreases of softening point, and the processability and surface gloss will improve, but the strength will decrease. Otherwise, with the decrease of MI, the molecular weight will increase, and the impact performance and environmental stress crack resistance will be improved.

Application

- It is widely used in packaging molds, fitness products, hot melt adhesives, toys and other fields.

- Vinyl acetate content between 5% and 10% are elastic films, etc.

- EVA with 20-28% vinyl acetate is mainly used for hot melt adhesives and coating products;

- Vinyl acetate content between 5%~45% are mainly films (including agricultural films) and sheets.

(1) Foam shoe material. Shoe material is the most important application of EVA resin in our country. In the EVA resin used in shoe materials, the vinyl acetate content is generally account for 15% to 22%.

(2) Film. The main purpose of EVA film is to produce functional greenhouse film. Functional greenhouse film features high weather resistance, anti-fogging and heat preservation. Considering polyethylene is not polar, even if a certain amount of anti-fogging agent is added, its anti-fogging performance can only be maintained for about 2 months.

(3) Wire and Cable. With the continuous development of computer and network engineering, people tend to use halogen-free flame-retardant cables and silane cross-linked cables for the safety of computer rooms.

(4) Toy. EVA resin is also widely applied in toys, such as children’s wheels and seat cushions.

(5) Hot melt adhesive.

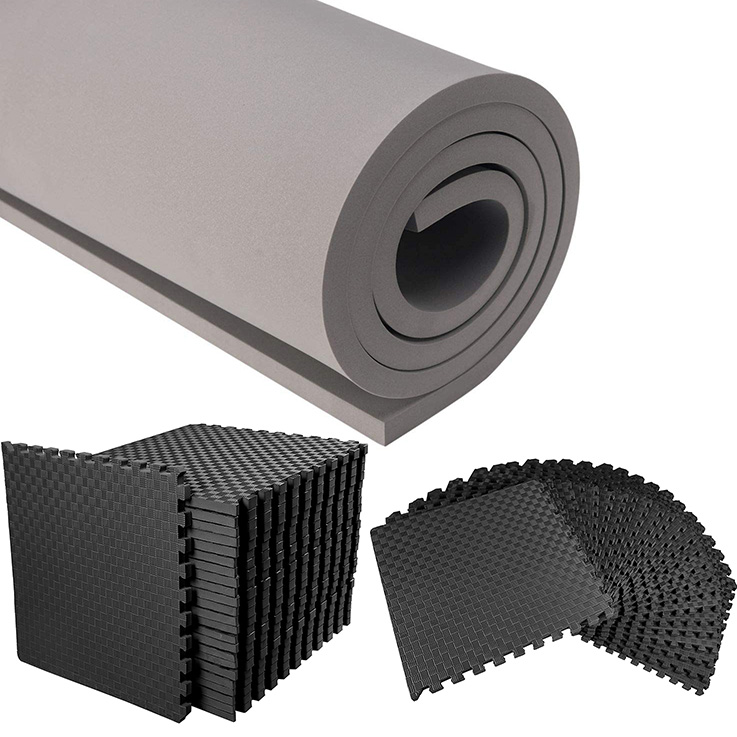

(6) Yoga mat, fitness mat. Yoga mat manufacturers purchases a large amount of EVA raw materials every year.

(7) Other application. EVA resin is also widely used in the fields of inks, bags, wine bottle cushions, etc. It is estimated that EVA resin is not less than 15 kt in these products.

① Material description Specification and level Hot melt Appearance color

The material is used for compounding, extrusion, adhesive, sealant and wax mixture

Remarks Heat stabilizer: BHT antioxidant

②Processing conditions Processing conditions

③Technical data of raw materials

Classified by purpose:

(1) Film, sheet and laminated products.

(2) General supplies: EVA resin has the advantages of flexibility, resistance to environmental stress cracking, and good weather resistance. So it is suitable for industrial materials such as power wire insulation bags, household appliances accessories, window sealing materials, etc.

(3) Daily groceries include sporting goods, toys, cushions, straps, airtight container covers, EVA rubber footballs, etc.

(4) Auto parts.

(5) Foamed products: Pressurized foaming includes foam slippers, sandals, building materials, etc. Injection foaming includes various industrial parts, women’s shoe soles, hot melt adhesives, etc.

Do You Want To Make Custom Design Yoga Mat?

Drop Us An Email And You Will Receive Our Feedback Within 24 Hours.

As a leading yoga mat manufacturer, Speck Group focuses on innovation, quality, simplicity, and sustainability.